Difference between revisions of "RISO PRINT GOCCO LAMP sintered silver nanowires"

Shihweichieh (talk | contribs) |

Shihweichieh (talk | contribs) m (→The setting of GOCCO LAMP Ag-NWs welding) |

||

| Line 13: | Line 13: | ||

</gallery> | </gallery> | ||

| − | ==The setting of GOCCO LAMP Ag-NWs welding== | + | ==The setting of GOCCO LAMP Ag-NWs welding and result== |

| − | The Ag-NWs samples are prepared by mixing few drops of 200ml of 70% ethanol with 0.18 grams of AgNWs. The solution is | + | The Ag-NWs samples are prepared by mixing few drops of 200ml of 70% ethanol with 0.18 grams of AgNWs. The solution is being ultrasoniced for 20 mins. The GOCCO bulbs are fixed on a DIY holder and the top of the bulb is about 1 cm above the Ag-NWs sample. The white light flash was triggered by short-circuit the bulb connector with a 9V battery. The SEM photo of the unweldered and weldered samples were compared below but no signs of any welding was found. Additionally, the colorized SEM photo shows there's some glues attached on the silver nanowires which might cause decrease of the conductivity, indicating the need of acetone bath before the white light exposure. Also, the reflective surface in the original GOCCO bulb case is needed to increase the exposure heat in order to obtain the expected Ag-NW networks. |

<gallery mode="traditional" widths=360px heights=240px caption="Welding setup with GOCCO LAMP"> | <gallery mode="traditional" widths=360px heights=240px caption="Welding setup with GOCCO LAMP"> | ||

File:RISO PRINT GACCO LAMP sintering for Ag-NW 01.jpg|DIY bulb holder for GOCCO LAMP. The white light flash was activated by a 9V battery with jumper wires. | File:RISO PRINT GACCO LAMP sintering for Ag-NW 01.jpg|DIY bulb holder for GOCCO LAMP. The white light flash was activated by a 9V battery with jumper wires. | ||

| Line 21: | Line 21: | ||

<gallery mode="traditional" widths=360px heights=240px caption="SEM of Ag-NWs comparisons"> | <gallery mode="traditional" widths=360px heights=240px caption="SEM of Ag-NWs comparisons"> | ||

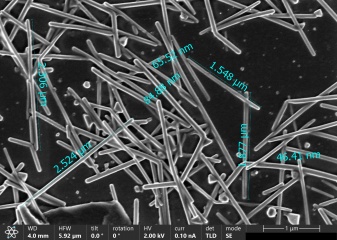

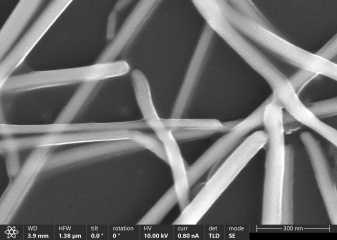

| − | File:Ag-NW_pristine_measurement .jpg|SEM photo of Ag-NWs with measurement at 1µm. | + | File:Ag-NW_pristine_measurement .jpg|SEM photo of the non-sintered Ag-NWs with measurement at 1µm. |

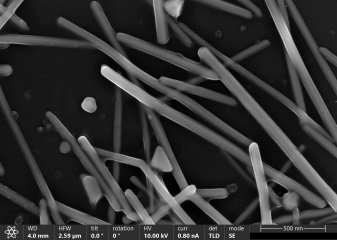

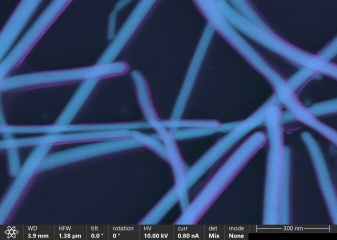

File:Ag-NW_pristine .jpg|SEM photos of the Ag-NWs after the GOCCO LAMP exposure at 500nm. | File:Ag-NW_pristine .jpg|SEM photos of the Ag-NWs after the GOCCO LAMP exposure at 500nm. | ||

File:Ag-NW_sintered.jpg|SEM photos of the Ag-NWs after the GOCCO LAMP exposure at 300nm. | File:Ag-NW_sintered.jpg|SEM photos of the Ag-NWs after the GOCCO LAMP exposure at 300nm. | ||

</gallery> | </gallery> | ||

| − | <gallery mode="traditional" widths=360px heights=240px caption="SEM of | + | <gallery mode="traditional" widths=360px heights=240px caption="Colorized SEM of Ag-NWs samples"> |

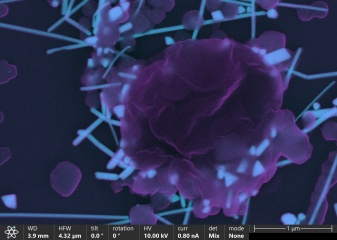

File:Ag-NW_sintered_art_by_Joakim copy.jpg|SEM nano art by Joakim Reuteler. | File:Ag-NW_sintered_art_by_Joakim copy.jpg|SEM nano art by Joakim Reuteler. | ||

File:Ag-NW_pristine_colorized.jpg|Colorised SEM photos of the Ag-NWs after the GOCCO LAMP exposure at 500nm. | File:Ag-NW_pristine_colorized.jpg|Colorised SEM photos of the Ag-NWs after the GOCCO LAMP exposure at 500nm. | ||

Latest revision as of 04:34, 21 November 2023

Contents

Abstract

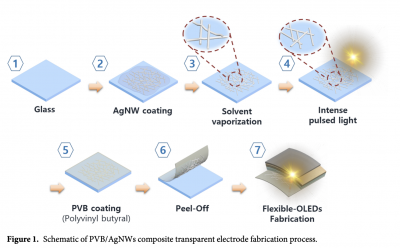

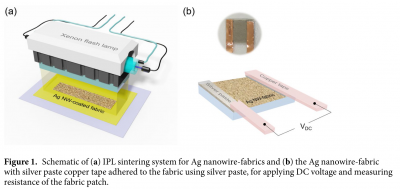

According to "Light welding of ultra-smooth and robust silver nanowire networks embedded in poly(vinyl-butyral) for flexible OLED" the welding of the Ag-NW conductive layer can be done by intensive pulse light (IPL), using strong white light to create heat to welder Ag-NWs to form a network to increase the conductivity. An alternative light source is performed in this experiment due to the difficulty to obtain expansive IPL. The Japanese toy kit "RISO PRINT GOCCO LAMP" introduced by the founder of Bioclub Tokyo, Georg Tremmel is a Japanese riso print kit that allow user to create personalized riso print mask by the heat created from the exploded light lamp provided in the kit. This experiment simply compares the conductivity of the Ag-NW layer before and after the exposure. The Ag-NWs used in this experiment is labelled "diameter < 100nm, length > 30 um".

The original RISO PRINT GOCCO LAMP kit

- The original RISO PRINT GOCCO LAMP kit

The setting of GOCCO LAMP Ag-NWs welding and result

The Ag-NWs samples are prepared by mixing few drops of 200ml of 70% ethanol with 0.18 grams of AgNWs. The solution is being ultrasoniced for 20 mins. The GOCCO bulbs are fixed on a DIY holder and the top of the bulb is about 1 cm above the Ag-NWs sample. The white light flash was triggered by short-circuit the bulb connector with a 9V battery. The SEM photo of the unweldered and weldered samples were compared below but no signs of any welding was found. Additionally, the colorized SEM photo shows there's some glues attached on the silver nanowires which might cause decrease of the conductivity, indicating the need of acetone bath before the white light exposure. Also, the reflective surface in the original GOCCO bulb case is needed to increase the exposure heat in order to obtain the expected Ag-NW networks.

- Welding setup with GOCCO LAMP

- SEM of Ag-NWs comparisons

- Colorized SEM of Ag-NWs samples

References

- The original usage of Riso print GOCCO lamp RISO PRINT GOCCO LAMP demonstration.

- Lee, Dong Jun, Youngsu Oh, Jae-Min Hong, Young Wook Park, and Byeong-Kwon Ju. 2018. “Light welding of Ultra-Smooth and Robust Silver Nanowire Networks Embedded in Poly(Vinyl-Butyral) for Flexible OLED.” Scientific Reports 8 (1): 14170. https://doi.org/10.1038/s41598-018-32590-0.

- Jin, Hwa-Young, Jae-Yup Kim, Jin Ah Lee, Kwangsoo Lee, Kicheon Yoo, Doh-Kwon Lee, BongSoo Kim, et al. 2014. “Rapid welding of TiO2 Photoelectrodes Using Intense Pulsed White Light for Flexible Dye-Sensitized Solar Cells.” Applied Physics Letters 104 (14): 143902. https://doi.org/10.1063/1.4871370.