Difference between revisions of "Mineral fiber based TiO2 photo-electrode in DSSC"

Shihweichieh (talk | contribs) m (→The counter-electrode) |

Shihweichieh (talk | contribs) m (→The counter-electrode and the electrolyte) |

||

| Line 7: | Line 7: | ||

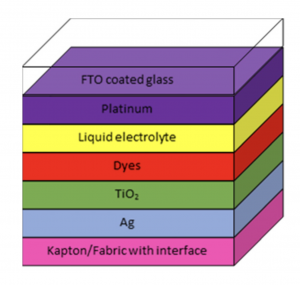

| + | [[File:textile based DSSC structure diagram1.jpg|thumb|Reference (a) of the textile based DSSC structure. See [https://ieeexplore.ieee.org/document/8721081/ "Processing of Printed Dye Sensitized Solar Cells on Woven Textiles".]]] | ||

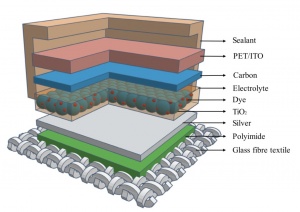

| + | [[File:textile based DSSC structure diagram2.png|thumb|Reference (b) of the textile based DSSC structure.]] | ||

| − | + | <gallery mode=slideshow> | |

| − | <gallery> | + | File:IMG_2490.JPG |

| − | File: | + | File:textilel based tio2 photoelectrode soaking in N719 dye.jpg |

| − | File: | + | File:backside of the tio2 photo-electrode sputtered with silver coating.jpg |

| − | File: | + | File:IMG_2565.JPG |

File:Dyeing woven photo-electrode in N719 dye.jpg | File:Dyeing woven photo-electrode in N719 dye.jpg | ||

| + | File:Sintered and dyed 18NR-AO TiO2 on FILAVA WF.jpg | ||

File:front side of microscopy of sintered and dyed 18NR-AO TiO2 on FILAVA WF.jpg | File:front side of microscopy of sintered and dyed 18NR-AO TiO2 on FILAVA WF.jpg | ||

File:back side of microscopy of sintered and dyed 18NR-AO TiO2 on FILAVA WF.jpg | File:back side of microscopy of sintered and dyed 18NR-AO TiO2 on FILAVA WF.jpg | ||

| − | |||

</gallery> | </gallery> | ||

Revision as of 19:02, 23 October 2023

First prototype

The woven photo-electrode

The TiO2 paste 18NR-AO purchased from Greatcell Solar is coated onto the mineral woven fabric provided by Isomatex by doctor-blade method. The fabric is then fired with conventional kitchen electric stove under 400˚C to 440˚C and it's soaked into annatto dyes for 5 hours after cooling down. The final piece appears in golden color after dyeing process is completed. The backside of the fabric is coated with silver paste (A729) by the doctor-blade method and is cured in 200˚C. Finally the fabric is soaked in N719 dye for 5 hours.

The counter-electrode and the electrolyte

A piece of ITO PET film is used as counter-electrode, the conductive side is coated with carbon layer by penile scratching. Few drops of EL-HTE High Temperature Electrolyte purchased from Greatcell solar was added on the surface of the photo-electrode, then the ITO PET film is glued on top of it with TPU film by a heat press machine.

Data sheet of Woven Fabric from ISOMATEX S.A. File:Woven-Fabrics-TDS-ISMTX.pdf