Guava seeds synthesized silver nanowires

Contents

Part I, the bio synthesis of Ag-NWs

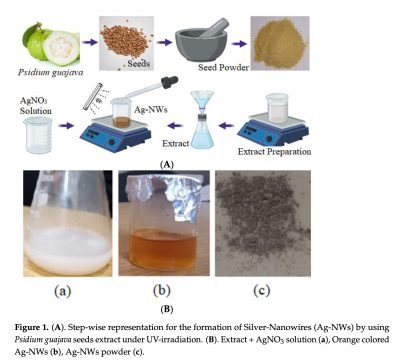

This experiment is composed with two existed paper, one is to synthesis AgNWs with Psidium Guajava seed, and the other one is to synthesis transparent conductive layer by transferring AgNWs which are light sintered by Riso print Gocco lamps. Guava seeds contain some compounds, such as polyphenols and alkaloids, which can reduce silver nitrate under certain conditions, thereby promoting the growth and stability of silver nanowires. These compounds acted as reducing agents and stabilizers during the preparation process, thus enabling a green synthesis method without external stabilizers. For the light sintering of AgNWs, a local Japanese toy kit "RISO PRINT GOCCO LAMP" is used to replace the IPL (intense pulsed light) in the original paper. The sintered AgNWs is formed on glass and then be transferred to a PVB film.

The synthesis of AgNWs with guava seed

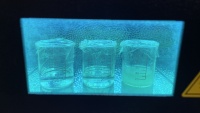

3 beakers of mixtures of silver nitrate and guava seed extraction were created with different concentration of guava seed extraction, 1. silver nitrate solution mixed with distilled water, 2. silver nitrate solution mixed with guava seed extraction heat stirred for 50 mins, 3. silver nitrate solution mixed with guava seed extraction heat stirred for 4 hours. All beakers are put under UV exposure for 4 hours, the color of the second and 3rd mixture were changed from milky white to orange. The black material floating on the final solution was collected by dropper and store in test tube.

- Preparation of the guava seed. The guava seed was collected from one Taiwanese guava by hand, then it is dried in an oven under 50ºC for 48 hours and powdered by a pharmacy pestle.

- Mix 0.1g of the guava seed powder with 100ml distilled water, and it's stirred under 40ºC for 50 minutes. Filter out the seeds from the extraction solution.

- Prepare 1mM silver nitrate solution by dissolving 1.7 grams of silver nitrate in 100 ml of distilled water.

- Mix the silver nitrate solution and extraction of Taiwan guava seed by the ratio of 2:1.

- Put the mixed solution under UV exposure for 4 hours, the beakers are sealed with cling film.

- Collect the AgNWs solution. (yet to know how to collect it exactly)

Collect the silver nanowires

To collect the silver nanowires, you should focus on isolating the silver matter floating on the solution surface, as this is likely the nanowire component. Here's a step-by-step guide on how to collect the silver nanowires using a centrifuge and filter paper:

- Centrifuge the solution: Transfer the entire reaction mixture, including the orange solution and the floating silver matter, to centrifuge tubes. Ensure that the tubes are suitable for centrifugation and can withstand the required speed.

- Centrifugation: Place the centrifuge tubes into the centrifuge and run it at a suitable speed and time to separate the silver nanowires from the solution. The centrifugal force will cause the heavier silver nanowires to separate from the solution and collect at the bottom of the tubes.

- Remove the supernatant: After centrifugation, carefully remove the tubes from the centrifuge. The centrifugation process should have caused the silver nanowires to form a pellet at the bottom of the tubes, while the orange solution (containing smaller nanoparticles) should be present as the supernatant liquid above the pellet.

- Discard the supernatant: Gently pour off or aspirate the supernatant liquid containing the orange solution without disturbing the pellet of silver nanowires at the bottom. Be cautious not to disturb the nanowire pellet during this step.

- Wash the nanowires: To remove any remaining contaminants or unreacted species, you can wash the silver nanowire pellet. Add a suitable solvent, such as ethanol or water, to the tubes and resuspend the pellet. Then, centrifuge again to separate the nanowires from the washing solvent. Repeat this washing process a couple of times to ensure proper purification.

- Dry the nanowires: After washing, you can either air-dry the nanowires or use a gentle heat source to evaporate the solvent and dry the nanowires. It's essential to be gentle during the drying process to maintain the integrity of the nanowires.

- Collect the dried nanowires: Once dried, carefully remove the silver nanowires from the centrifuge tubes using a spatula or another suitable tool. You now have the purified silver nanowires ready for further analysis or application.

UV-vis analysis of AgNWs

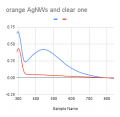

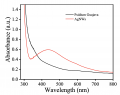

The Ultraviolet–visible spectroscopy test was supported by Shohei Asami, member of Bioclub, he's currently in his doctoral studies. He had the sample testified by the machine in his company laboratory. UV-Vis spectra of Ag-NWs synthesis with Taiwan guava seeds, datais provided by Shohei Asami. The result match up the graph in the paper, but it's overall lower, it might due to its lower density.

- UV-vis result of the final solution

SEM result

The scanning electron microscopy is kindly supported by Joakim Reuteler in ETH Zurich. 2 samples of guava seeds synthesised AgNWs were prepared, one is AgNW solution dried on glass, the other one is aggregation collected from the solution. However we didn't find any wire-alike shape, indicating the failure of the nano wire synthesis.

- SEM images of the final solutions

Part II, Gacco Lamp Sintered AgNWs PVM film

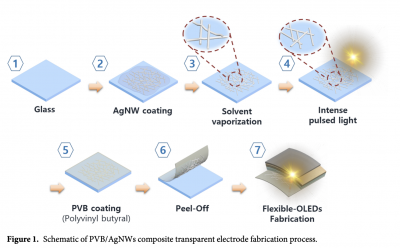

Continued with the first part, in the original paper, the AgNWs is sintered by IPL (intense pulsed light) but due to the high price of IPL, I decided to try something else. I found a type of light bulb that generate sudden high heat in a Japanese toy kit RISO PRINT GOCCO LAMP which is introduced by the founder of Bioclub, Georg Tremmel. The original purpose of the bulb is to create mask for riso print. The original usage please visit RISO PRINT GOCCO LAMP tutorial. The follow on practices is documented in page Conductive thin coating made of AgNWs.

A conductive, uniform, and ultra-smooth flexible transparent composite film is produced by embedding silver nanowires (AgNWs) into poly(vinyl-butyral) (PVB) without pressure or high-temperature annealing.

Preferences

- Ali, Faisal, Zahid Ali, Umer Younas, Awais Ahmad, Ghulam Mooin Ud Din, Muhammad Pervaiz, Rafael Luque, et al. 2021. “UV-Light Mediated Biosynthesis of Silver Nanowires; Characterization, Dye Degradation Potential and Kinetic Studies.” Sustainability 13 (November): 13220. https://doi.org/10.3390/su132313220.

- Lv, Pengfei, Huimin Zhou, Min Zhao, Dawei Li, Keyu Lu, Di Wang, Jieyu Huang, Yibing Cai, Lucian Amerigo Lucia, and Qufu Wei. 2018. “Highly Flexible, Transparent, and Conductive Silver Nanowire-Attached Bacterial Cellulose Conductors.” Cellulose 25 (6): 3189–96. https://doi.org/10.1007/s10570-018-1773-8.

- Ferraro, Giovanni, and Emiliano Fratini. 2019. “A Simple Synthetic Approach To Prepare Silver Elongated Nanostructures: From Nanorods to Nanowires.” Journal of Chemical Education 96 (3): 553–57. https://doi.org/10.1021/acs.jchemed.8b00628.

- Padhi, Santwana, and Anindita Behera. 2022. “Chapter 17 - Biosynthesis of Silver Nanoparticles: Synthesis, Mechanism, and Characterization.” In Agri-Waste and Microbes for Production of Sustainable Nanomaterials, edited by Kamel A. Abd-Elsalam, Rajiv Periakaruppan, and S. Rajeshkumar, 397–440. Nanobiotechnology for Plant Protection. Elsevier. https://doi.org/10.1016/B978-0-12-823575-1.00008-1.

- Lee, Dong Jun, Youngsu Oh, Jae-Min Hong, Young Wook Park, and Byeong-Kwon Ju. 2018. “Light Sintering of Ultra-Smooth and Robust Silver Nanowire Networks Embedded in Poly(Vinyl-Butyral) for Flexible OLED.” Scientific Reports 8 (1): 14170. https://doi.org/10.1038/s41598-018-32590-0.

- Jin, Hwa-Young, Jae-Yup Kim, Jin Ah Lee, Kwangsoo Lee, Kicheon Yoo, Doh-Kwon Lee, BongSoo Kim, et al. 2014. “Rapid Sintering of TiO2 Photoelectrodes Using Intense Pulsed White Light for Flexible Dye-Sensitized Solar Cells.” Applied Physics Letters 104 (14): 143902. https://doi.org/10.1063/1.4871370.