Wild OpenPCR

Contents

OpenPCR in the wild

Attempt to build an OpenPCR just from the description on the website OpenPCR without a kit or any supplied parts.

call it free/libre open source

There is two aspects to open source hard and software. The one is to build an new product in a community, include different people and skills, combine ideas in the process. To do so developers share files and knowledge openly. And once the product is completed, "consumers" can buy the product like any other product without knowing much about it. Maybe they build it from a kit to get it cheaper and learn a bit about how the product looks inside.

The other openness, some call it free/libre open source, does not distinguish so much between developers and consumers. Everyone should be able to have access to the design, source the parts, build the device, modify it, make derived works, redistribute and use it commercially. To be that open, more information than just source files is needed... with the present rebuild of the OpenPCR I try contribute some to this...

I think people around OpenPCR did a great job. The OpenPCR is well constructed and seems to work if everything is put together properly. To rebuild it just from the information on the OpenPCR website is not easy. And some parts are not open source (like the lid heater). With some reverse engineering (some important details can be found in the code) it is still possible as the present rebuild shows. And Josh Perfetto form the OpenPCR team responded to all our emails and helped with open and precise answers. Thank you.

Here we go:

The OpenPCR bill of materials (BOM) can be found here:

https://docs.google.com/a/snowrise.com/spreadsheet/ccc?key=0AiaWH3PL_9CndG1GbmtSZ1I3aGdkQkE4YVhwZ3o5c1E#gid=0

Good to know.

So what do we need?

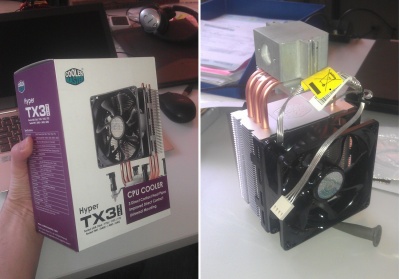

- The PC-Cooler with 90° heat pipe is easy to get for around 20 euro.

- The nice and small power supply that fits into the housing is not so easy. It is a "Flex 1u PC Power Supply 200 W ATX. Bigger (standard size is more easy and should do, just won't fit into the housing

- Arduino ok, SMD driver board with AD converter, connectors, feasible. Will try to simplify the layout to make it single-side DIY. What are the big resistors for? Some kind of heating? Have to figure out.

- LCD Display - standard, anything goes, 4 Lines are nice.<vr>

- Heat block and pelter element. Hmm...

- The heated lid. Seems to be important to avoid condensation. Should be simple with any heating element capable to go up to about 100 C. Without lid heating one could just put a layer of mineral oil on top in each tube too.

Laser Cut Housing

First and easy thing is to go up to a FabLab and laser cut the wood parts for the housing. Need to get the files from the website and have the most recent version of SolidWorks to extract the drawings...

Et voila:

And the one pdf with all the parts as of November 2012:

File:Pcr laserfiles.pdf

Got some additional information from Josh from OpenPCR: The downloadable files are the more recent versions of our design.

Heat Block and Peltier Element

Now one tricky part is the heatblock and the peltier element. For those we have two nice hacks:

1. A peltier element with the exact right dimensions and with some luck even the rough thermo-block can be found in one of those little electric fridges:

Found those in electronic waste.

Unscrew the blower and the cooler and you will find the peltier element.

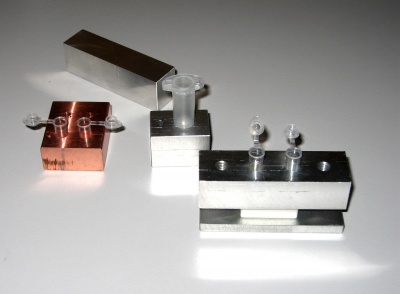

All you need, a aluminium heat-block (think the original OpenPCR heat-block is cooper and then chromed, right?), peltier element...

2. Now that we have the heating/cooling element and the block we need to get the right holes for the eppendorf tubes in it.

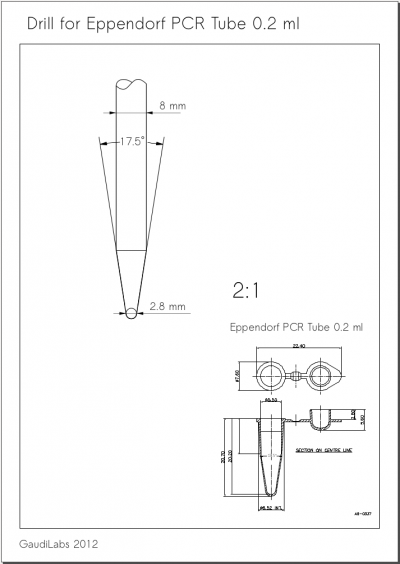

Josh says from his experience: "Different manufacturers make 200 ul tubes of different dimensions. But we designed OpenPCR around the key angle of 17.5 degree cone angle, which seems to work for most PCR tubes. Good luck in your endeavors".

So with a fried we designed a special milling tool around this angle. We make this an "Open Shared Hardware Tool", so who ever needs to make some nice 17.5 degree holes may borrow these for a while :-)

This is the drawing with dimensions:

File:Pcr eppendorf milling tool 02.pdf

File:Pcr eppendorf milling tool 15.pdf

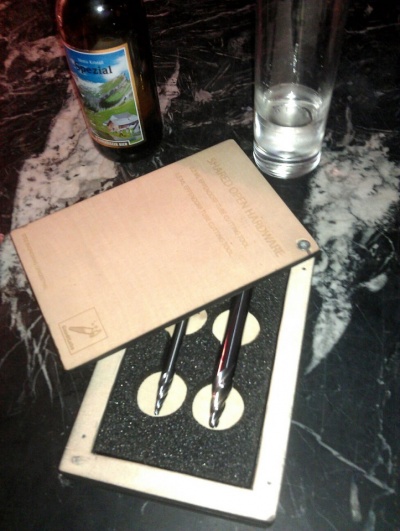

And the ready made tools:

Here different thermo-blocks made with the tools:

Went up to a local tech shop and drilled the holes in the aluminum block with our nice tools. Did a really bad job though. The divisions on the old milling machine were different for all axes (2.5mm, 4mm, 3mm) this is why all the holes are so weird.

The drilling tool worked pretty well, drilled a 2.5 mm hole first. The depth of all holes should be equal.

The Electronics

This is the PC blower I found (90°, with heat pipe), seems to fit pretty well:

The Electronics:

While the mechanical concept and construction is pretty well done, the people who built the electronics for the OpenPCR could have needed some help I guess... some things I still don't quite understand and some remarks:

- The PCB is probably auto routed witch usually turns out not so good...(lines to close, pads to small, parts not well arranges)

- Judging form the number of components it should be possible to fit all on a single sided (even smaller) board. That would make the rebuild with home etched PCBs easier.

- The two big resistors are to meet the minimum current demands of the switching power supply... hmm

- Is the extra AD converter really needed?

- The two big (heating) resistors are just next to the resistors used for the temperature sensor.

- Connecting a peltier element that consumes some 6-8 ampers with such a small connector is not optimal

- Why place the connector for the temperature sensor just next (below) the LCD connector

- Why resistors at the input lines of a digital circuit and FET transistor?

- SMD components... (I like it)

What ever, let's do it:

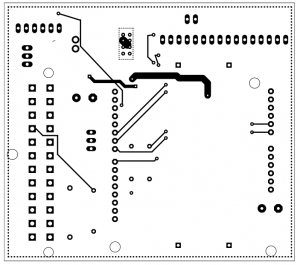

Modified the PCB as little as possible (around the SMD driver) just to make it doable in single sided. Turned out to be quite ugly with all the bridges and fixes. Would suggest to redesign completely if you do not want to order the double sided PCB. Who wants do redesign OpenPCR-PCB?

The single side design I used:

File:Pcr singlesidePCB.pdf

With those brides to be added:

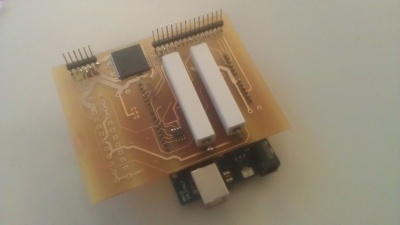

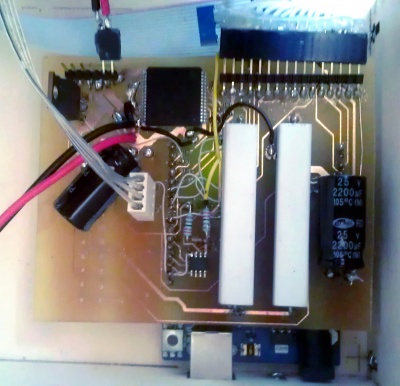

PCB with reflow soldered SMD parts... looks ok. Did not put the ATX connector.

And pretty messy with all the jumpers to compensate for the second layer...

Still it works.

Connecting the LCD:

- Most LCDs need a potentiometer to adjust for the contrast (on PIN 3, VEE). Had to add this to the OpenPCR print. Don't know how they do it (with a digital pin?)

- My LCD also needed a resistor to limit the current to the back-light...

(please consider when redesigning)...

Connecting the blower

Some blower have 4 pin connectors... just the first three are needed. Pin 1 (GND) is usually marked black.