Difference between revisions of "Mineral fiber based TiO2 photo-electrode in DSSC"

Shihweichieh (talk | contribs) m (Shihweichieh moved page Sintering TiO2 porous layer on mineral fabric to Mineral fiber based TiO2 photo-electrode in DSSC) |

Shihweichieh (talk | contribs) |

||

| Line 1: | Line 1: | ||

| − | == | + | =Abstract= |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

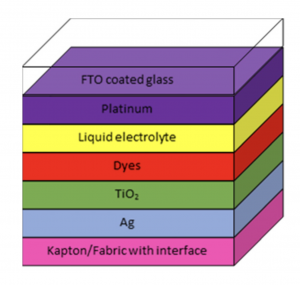

[[File:textile based DSSC structure diagram1.jpg|thumb|Reference (a) of the textile based DSSC structure. See [https://ieeexplore.ieee.org/document/8721081/ "Processing of Printed Dye Sensitized Solar Cells on Woven Textiles".]]] | [[File:textile based DSSC structure diagram1.jpg|thumb|Reference (a) of the textile based DSSC structure. See [https://ieeexplore.ieee.org/document/8721081/ "Processing of Printed Dye Sensitized Solar Cells on Woven Textiles".]]] | ||

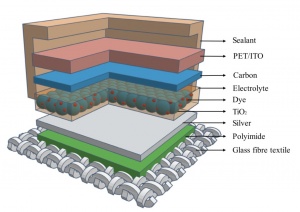

[[File:textile based DSSC structure diagram2.png|thumb|Reference (b) of the textile based DSSC structure.]] | [[File:textile based DSSC structure diagram2.png|thumb|Reference (b) of the textile based DSSC structure.]] | ||

| − | + | This experiment is the first step to achieve a textile based dye sensitized solar cell. In this experiment, the process of making a textile based TiO2 photo-electrode is documented. The experiment mainly reference the structures bases on two papers ""Processing of Printed Dye Sensitized Solar Cells on Woven Textiles" and "Screen Printed Dye-Sensitized Solar Cells (DSSCs) on Woven Polyester Cotton Fabric for Wearable Energy Harvesting Applications". The reason to chose these structures is because there is less expansive materials or high technology process are employed in these structures. A mineral textile sample FILAVA was provided by Isomatex S.A., the melting point of the FILAVA yarn is at 1560˚C, therefore it is able to sinter the 18NR-AO TiO2 paste purchased from Greatcell Solar on the textile sample with the conventional heat sintering method with 420-450˚C. | |

| + | =The photo-electrode= | ||

| + | #The 18NR-AO paste is coated onto the FILAVA woven textile by Doctor Blade technique. | ||

| + | #The woven fabric is then fired with a kitchen electric stove at 400˚C to 420˚C to completed the sinter. The color change of the TiO2 sintering (from white to dark brown and back to white) is well performed during the heating process. | ||

| + | #The sintered sample is soaked into annatto dyes for 5 hours after its cooling down. The yarn is also dyed and appears in golden color from the dyeing process. | ||

| + | #The backside of the fabric is coated with silver paste (725A) purchased from Acheson by the Doctor Blade method and is cured in 120˚C for 15 minutes. | ||

| + | #Finally the fabric is soaked in N719 dye for the second dyeing for 5 hours in order to increase the efficiency. The golden color of the yarn is also bleached after the second dyeing (optional). | ||

<gallery mode=slideshow> | <gallery mode=slideshow> | ||

| − | File:IMG_2490.JPG | + | File:IMG_2490.JPG|FILAVA textile based TiO2 photo-electrode. |

| − | File: | + | File:Dyeing woven photo-electrode in N719 dye.jpg|The photo-electrode is dyed in annatto dye. |

| − | + | File:textilel based tio2 photoelectrode soaking in N719 dye.jpg|The photo-electrode is dyed in N719 dye. | |

| − | File: | + | File:Sintered and dyed 18NR-AO TiO2 on FILAVA WF.jpg|The dyed FILAVA photo-electrode appearing in gold color. |

| − | + | File:IMG_2565.JPG|Microscopy of the 18NR-AO sintered on FILAVA fabric. | |

| − | File:Sintered and dyed 18NR-AO TiO2 on FILAVA WF.jpg | + | File:front side of microscopy of sintered and dyed 18NR-AO TiO2 on FILAVA WF.jpg|Microscopy of the front side of the FILAVA photo-electrode. |

| − | File:front side of microscopy of sintered and dyed 18NR-AO TiO2 on FILAVA WF.jpg | + | File:back side of microscopy of sintered and dyed 18NR-AO TiO2 on FILAVA WF.jpg|Microscopy of the back side of the FILAVA photo-electrode. |

| − | File:back side of microscopy of sintered and dyed 18NR-AO TiO2 on FILAVA WF.jpg | ||

</gallery> | </gallery> | ||

| + | =References= | ||

| + | #Opwis, Klaus, Jochen Stefan Gutmann, Ana Rosa Lagunas Alonso, Maria Jesus Rodriguez Henche, Mikel Ezquer Mayo, Fanny Breuil, Enrico Leonardi, and Luca Sorbello. 2016. “Preparation of a Textile-Based Dye-Sensitized Solar Cell.” International Journal of Photoenergy 2016: 1–11. https://doi.org/10.1155/2016/3796074. | ||

| + | #Liu, J., Y. Li, S. Arumugam, J. Tudor, and S. Beeby. 2018. “Screen Printed Dye-Sensitized Solar Cells (DSSCs) on Woven Polyester Cotton Fabric for Wearable Energy Harvesting Applications.” Materials Today: Proceedings 5 (5): 13753–58. https://doi.org/10.1016/j.matpr.2018.02.015. | ||

| + | #Liu, Jingqi, Yi Li, Menglong Li, Sasikumar Arumugam, and Stephen P Beeby. 2019. “Processing of Printed Dye Sensitized Solar Cells on Woven Textiles.” IEEE Journal of Photovoltaics 9 (4): 1020–24. https://doi.org/10.1109/JPHOTOV.2019.2899432. | ||

| + | #Satharasinghe, Achala, Theodore Hughes-Riley, and Tilak Dias. 2020. “A Review of Solar Energy Harvesting Electronic Textiles.” Sensors 20 (20): 5938. https://doi.org/10.3390/s20205938. | ||

| + | #Wirtanen, Sandra. 2018. “Solar Cells inside Woven Textiles.” https://aaltodoc.aalto.fi:443/handle/123456789/35870. | ||

| − | + | =Technical datasheets= | |

| − | Data sheet of Woven Fabric from ISOMATEX S.A. | + | #Data sheet of Woven Fabric from ISOMATEX S.A. [[:File:Woven-Fabrics-TDS-ISMTX.pdf]] |

| − | [[:File:Woven-Fabrics-TDS-ISMTX.pdf]] | + | #725A silver paste datasheet [[:File:TDS of 725A (6S-61).pdf]] |

Revision as of 20:05, 23 October 2023

Abstract

This experiment is the first step to achieve a textile based dye sensitized solar cell. In this experiment, the process of making a textile based TiO2 photo-electrode is documented. The experiment mainly reference the structures bases on two papers ""Processing of Printed Dye Sensitized Solar Cells on Woven Textiles" and "Screen Printed Dye-Sensitized Solar Cells (DSSCs) on Woven Polyester Cotton Fabric for Wearable Energy Harvesting Applications". The reason to chose these structures is because there is less expansive materials or high technology process are employed in these structures. A mineral textile sample FILAVA was provided by Isomatex S.A., the melting point of the FILAVA yarn is at 1560˚C, therefore it is able to sinter the 18NR-AO TiO2 paste purchased from Greatcell Solar on the textile sample with the conventional heat sintering method with 420-450˚C.

The photo-electrode

- The 18NR-AO paste is coated onto the FILAVA woven textile by Doctor Blade technique.

- The woven fabric is then fired with a kitchen electric stove at 400˚C to 420˚C to completed the sinter. The color change of the TiO2 sintering (from white to dark brown and back to white) is well performed during the heating process.

- The sintered sample is soaked into annatto dyes for 5 hours after its cooling down. The yarn is also dyed and appears in golden color from the dyeing process.

- The backside of the fabric is coated with silver paste (725A) purchased from Acheson by the Doctor Blade method and is cured in 120˚C for 15 minutes.

- Finally the fabric is soaked in N719 dye for the second dyeing for 5 hours in order to increase the efficiency. The golden color of the yarn is also bleached after the second dyeing (optional).

References

- Opwis, Klaus, Jochen Stefan Gutmann, Ana Rosa Lagunas Alonso, Maria Jesus Rodriguez Henche, Mikel Ezquer Mayo, Fanny Breuil, Enrico Leonardi, and Luca Sorbello. 2016. “Preparation of a Textile-Based Dye-Sensitized Solar Cell.” International Journal of Photoenergy 2016: 1–11. https://doi.org/10.1155/2016/3796074.

- Liu, J., Y. Li, S. Arumugam, J. Tudor, and S. Beeby. 2018. “Screen Printed Dye-Sensitized Solar Cells (DSSCs) on Woven Polyester Cotton Fabric for Wearable Energy Harvesting Applications.” Materials Today: Proceedings 5 (5): 13753–58. https://doi.org/10.1016/j.matpr.2018.02.015.

- Liu, Jingqi, Yi Li, Menglong Li, Sasikumar Arumugam, and Stephen P Beeby. 2019. “Processing of Printed Dye Sensitized Solar Cells on Woven Textiles.” IEEE Journal of Photovoltaics 9 (4): 1020–24. https://doi.org/10.1109/JPHOTOV.2019.2899432.

- Satharasinghe, Achala, Theodore Hughes-Riley, and Tilak Dias. 2020. “A Review of Solar Energy Harvesting Electronic Textiles.” Sensors 20 (20): 5938. https://doi.org/10.3390/s20205938.

- Wirtanen, Sandra. 2018. “Solar Cells inside Woven Textiles.” https://aaltodoc.aalto.fi:443/handle/123456789/35870.

Technical datasheets

- Data sheet of Woven Fabric from ISOMATEX S.A. File:Woven-Fabrics-TDS-ISMTX.pdf

- 725A silver paste datasheet File:TDS of 725A (6S-61).pdf