Say Cheese

With a little bit of rennet, we decided to make cheese in Yogyakarta, based on the Neufchatel recipe on the site Cheese Making for Beginners.

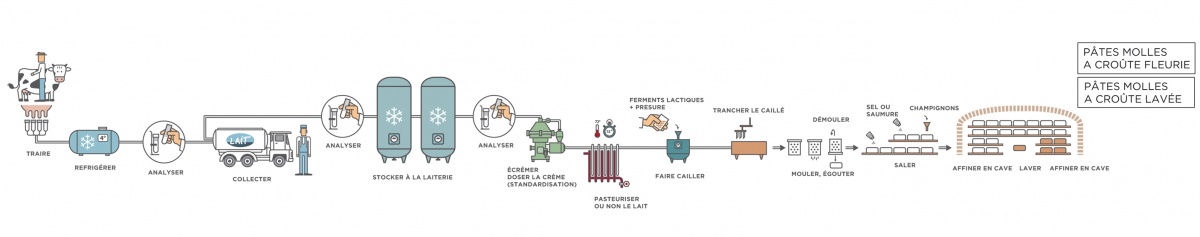

Pic from here [1]

Contents

Hackteria's Hagen Chääsli - Test 1

see main page: http://hackteria.org/?p=2634

Preparations

Ingredients

Step by Step

should be ready in November for the Hagen Lecture series...

Open Cheese Press

Cheesy Links

Hier der versprochene Link zu den „Chäs Forschern“

Und hier ihr paper:

https://www.cell.com/cell/fulltext/S0092-8674(14)00745-4

OpenLab (Germanism of Rennet), part of the Open Cheese Project

http://en.wikipedia.org/wiki/Chymosin#Recombinant_Chymosin

http://www.cheesescience.net/2008/07/what-is-fermentation-produced-chymosin.html

discussion on DIYbio: https://groups.google.com/forum/#!topic/diybio/DZEJODpUptM

Yeasts

https://en.wikipedia.org/wiki/Kluyveromyces_lactis

stuff about patents

Patent on Camel derived Chymosin: http://www.google.com/patents/EP2117331A1?cl=en

Microbially produced rennet, methods for its production and plasmids used for its production http://www.google.com/patents/EP0116778A1?cl=en

recovery stuff http://www.google.com/patents/US4721673

http://www.google.com/patents/US5215908

some more links

from http://www.transgen.de/pdf/datenbank/chymosin_phytase.pdf

1. Chymosin, pure source of rennet provides unlimited availability to the cheese industry The production process of cheese coagulation of milk proteins to ‘curds’ is achieved by the proteolytic activity of rennet added to milk. Rennet products obtained from suckling calves’ stomachs have traditionally been used for this. However, for various reasons such as milk quota and fluctuating veal production, the number of suckling calves available for slaughter is declining. Consequently, there has been a corresponding reduction in the quantity of calves’ stomachs available for use as a source of rennet. On the other hand, there is increasing demand for rennet as the world production of cheese is steadily increasing. In the early eighties, Gist-brocades started research on making calves’ rennet by fermentation of a genetically modified micro-organism. After an extensive evaluation of several possible hosts, it was decided to clone and express the DNA coding for calve stomach chymosin in an industrial strain of Kluy6eromyces lactis. The natural habitat of K. lactis is milk and milk products. The yeast has been isolated from fermented milk products like kefir, koumiss, yoghurt, and from a variety of cheeses. The yeast itself, when cultured on whey, was used in the 1950s and 1960s as an alimentary yeast with a high nutritional value in food and feed; in inactivated and dried form it was used in the 1960s and early 1970s as a health food and protein supplement. The micro-organism is known to be completely harmless and non-toxicogenic. K. lactis has been used for many years by Gist-brocades for the production of the food enzyme lactase which has been affirmed GRAS status by the US FDA. GRAS status applies to ingredients generally regarded as safe to be used in food. The industrial strain used for lactase production proved to be a suitable host to express the DNA coding for calf preprochymosin. With the aid of the yeast a-factor leader as a signal sequence the prochymosin is efficiently secreted into the medium. As K. lactis does not secrete appreciable amounts of endogenous proteins, the recovery of prochymosin can be very simple. The fermentation is followed by an acid step to autolyse prochymosin into active chymosin, the K. lactis biomass is subsequently removed by centrifugation or filtration and no further steps are required to obtain a chymosin preparation, brand name Maxiren® , with a much higher purity than traditional calves’ rennet. The chymosin in Maxiren® (Table 1) is absolutely identical to its natural counterpart in calves’ rennet, both chemically and biologically. This is based on molecular size, amino acid sequence and composition, immunochemical behaviour, and biochemical characteristics. Maxiren® has been commercially produced in the Gist-brocades enzyme plant at Seclin, France, since 1988. This ‘Installation Classe´e’ plant has also been authorised to use a genetically modified organism for production purposes. The plant has been awarded the ISO 9002 certificate as well as kosher certification. The product Maxiren® is a vegetarian product and is also kosher and halal approved. Maxiren® has been officially approved for sale to cheese manufacturers in the USA, Australia, a number of European countries, and countries in South America, Africa, and Asia. With the availability of chymosin made by genetically modified K. lactis, the cheese producing industry is no longer dependent on the supplies of calves’ stomach rennet. There is now an unlimited supply of cost-effective product of high and consistent purity, free of animal-source contaminants.