Elektrowetting

Contents

- 1 Communication / Maillist

- 2 Introduction

- 3 DIY experiment

- 4 DIY Designs

- 5 Fluxology

- 6 Flux Technologies

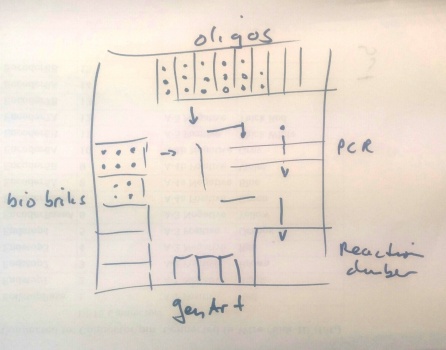

- 7 Bio Device

- 8 Surface Coating

- 9 Electronic Control

- 10 Visit to DropBot @ Helsinki University

- 11 Intense fluxing (hacking session)

- 12 Experiments replicated at Waag's Open Wetlab

- 13 References

- 14 Videos

- 15 Patents

Communication / Maillist

let's make a mail list on topics of labchip@hackteria.org

Introduction

- Electrical charge of the surface changes the shape of water drops (before 1875)

- Electrowetting is the modification of the wetting properties of a surface by applying different electric fields (1981)

- "fluid transistor" for manipulating chemical and biological fluids (1980)

- Electrowetting on this dielectric-coated surface, EWOD (1993)

- Digital Microfluidic Circuits

What you need:

- insulating dielectric and hydrophobic layers

- immiscible fluids

- DC or RF power

- mass arrays of miniature interleaved electrodes (Indium tin oxide (ITO))

- digital control

- nano droplets

What you can do:

- move droplets in linear, circular and directed paths

- pump fluids

- mix fluids

- fill reservoirs

- move droplets over sensors or heaters

- control fluid flow electronically or optically

source: http://en.wikipedia.org/wiki/Electrowetting

DIY experiment

What you need:

- ribbon cable

- water, oil

- high voltage (how high? Amperage? will 80v do?)

What you can do:

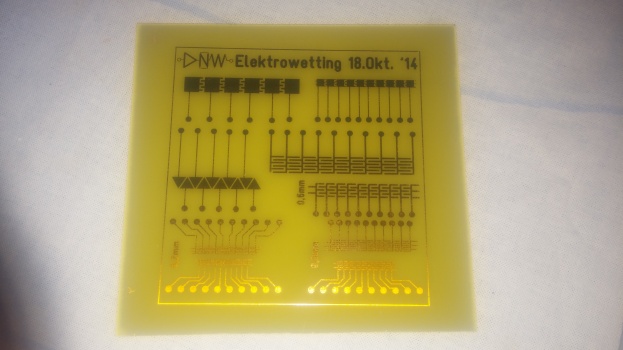

DIY Designs

Initial PCB Electrode designed by Philipp Meißner

Fluxology

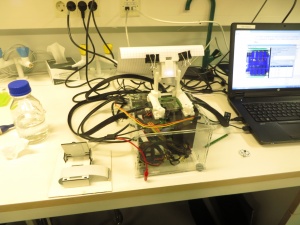

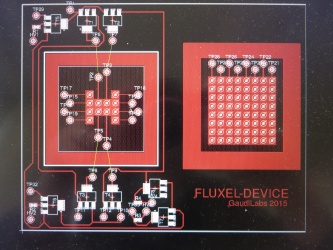

FluxMux-Device

Based on two crosswise flat ribbon cable the FluxMux device is an easy way to create a digital microfluidic device. An array of power leds shines through the grid to make drops visible.

The control is multiplexed.

Flux Technologies

comming soon...

Bio Device

Surface Coating

dusjagr used to work here in the ETH surface science group, and still has access to loads of knowledge and materials if needed.

Hydrophobic (Teflon-like) thin foils

We should try using thing PFA foils....

http://www.synthetica.de/en/PTFE_PFA_TFM_Folien_laminierte_Filme_(Crossfilm).html

http://www.nowofol.de/produkte/folien-aus-fluorpolymeren/nowoflon-pfa

http://www.mcmaster.com/#pfa-film/=x84831

From DropBot Dev Mailinglist

by Ryan Fobel:

CEP from Biddle Sawyer Corporation, USA:

Product: Cyanoethyl Pullulan ( Cyanoresin CR-S) Quantity: 100gms net Packing: Foil/mylar sealed bag

Standard Coatings: Teflon AF (NDA protection etc)

To Try: FluoroPel from http://www.cytonix.com

Surface Functionalization

Design of Surface Modifications for Nanoscale Sensor Applications, Sensors, 2015, 15, 1635-1675; doi:10.3390/s150101635

Download Paper: 2015_Reimhult Surface Modifications for Nanoscale Sensor

Kasemo, Bengt. 2002. “Biological Surface Science.” Surface Science 500 (March): 656–77. doi:10.1016/S0039-6028(01)01809-X.

Download Paper: File:kasemo_2002_biological_surface_science.pdf

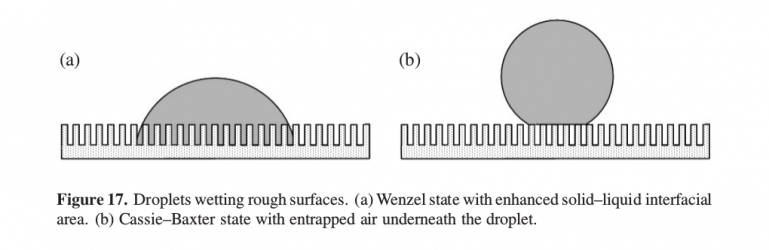

SuperHydrophobic Surfaces

Superhydrophobic self-cleaning surfaces are based on the surface micro/nanomorphologies; however, such surfaces are mechanically weak and stop functioning when exposed to oil. In March 2015, a group of scientists have published a paper on Science demonstrating a cheap and resistant super-amphiphobic coating (both water and oil repellent) that is incredibly resistant to scratches and oil exposure. Besides, this coating is also cool since it doesn't need to be cross-linked with surface like other perfluoro-silane based coatings.

They have created an ethanolic suspension of perfluorosilane-coated titanium dioxide nanoparticles that forms a paint that can be sprayed, dipped, or extruded onto both hard and soft materials to create a self-cleaning surface that functions even upon emersion in oil. Commercial adhesives were used to bond the paint to various substrates and promote robustness. These surfaces maintained their water repellency after finger-wipe, knife-scratch, and even 40 abrasion cycles with sandpaper. The formulations developed can be used on clothes, paper, glass, and steel for a myriad of self-cleaning applications.

Ready for some DIY-nanotech ?

Materials:

- Titanium Oxide (IV), anatase (rutile or mix should work too i guess), at 21nm (check: Degussa P25)

- Titanium Oxide (IV), anatase (rutile or mix should work too i guess), dual scale range at ~60-200 nm mixture

- 1H,1H,2H,2H-Perfluorooctyltriethoxysilane – cheapest source I found: http://www.alfa.com/en/catalog/B24620

- Absolute Ethanol

Tools:

- Becker

- Pasteur Pipette or Syringe

- DIY Magnetic Stirrer

Kitchen:

- add 1.00 g of 1H,1H,2H,2H-Perfluorooctyltriethoxysilane in 99.00 g of Ethanol and stir mechanically for two hours

- to the resulting solution, add 6 g of Titanium oxide (IV) nanopowder with a dual-scale range of particles at ~60-200 nm AND 6.00 g of Titanium oxide (IV) with primary particle at ~21 nm. Stir mechanically for 30 min

- This paint can be applied to solid or soft substrates. Methods of application include: dip-coating (120 cm /min), spray, or even simply a syringe needle (0.8*50 mm) to paint the substrates. In Ethanol solution, and depending on the substrate material, the paint need to be dried in air for at least 180 s before testing. Cold compressed air can be used to speed-up the process.

By buying low quanities, and with an estimated ratio of distribution of near 1 mL / 5 cm2 the average cost of coating per cm2 is: 0,122 €

The link to the paper is: http://www.sciencemag.org/content/347/6226/1132.abstract

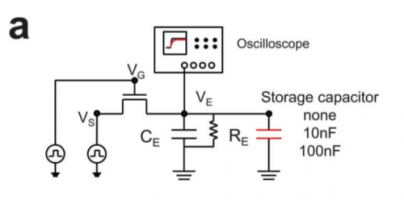

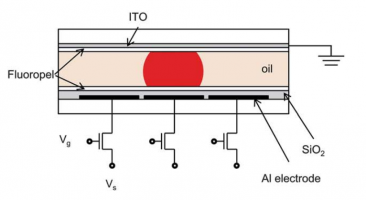

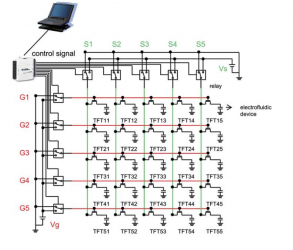

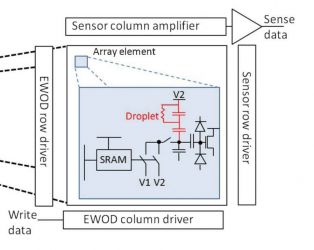

Electronic Control

[1,2,3]

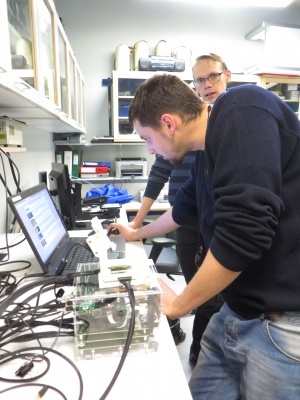

Visit to DropBot @ Helsinki University

== DigiFlux Shield ==file:///media/gaudi/CANON_DC/DCIM/124___03/IMG_7383.JPG

Layouting first prototype of DigiFlux with array of fluxels

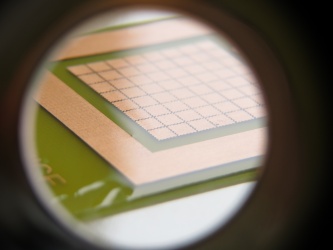

Etching some prototype shields.

Spin-coating with PDMS and teflon

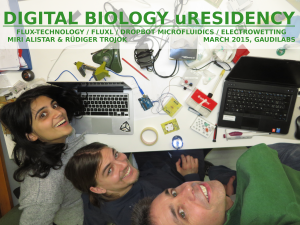

Intense fluxing (hacking session)

We met in gaudilabs to experiment on the fluxel device. We first learned how to control the device and how to apply the coating properly (saran wrap + rainX hydrophobic solution for car windows).We tested two bio-applications on fluxel: (1) growing E. coli DH5 alpha JM109 cells and (2) enzymatic reaction of β-galactosidase with Xgal.

For the first experiment, we wanted to investigate the impact of the electrical field on the growth of the E. coli cells. The setup consisted of the fluxel device, the arduino control, a webcam, a box and a computer with adequate software. We first dispensed a 30 μL droplet containing the E. coli cells on the fluxel device, covered it with a special lid to delay evaporation and then, carefully, we confined the fluxel device, the arduino and the webcam in a box. We put the box in the incubator and turned the fluxel device on. The droplet was incubated at 37°C. We monitored overnight the droplet using the ImageJ software running on a computer placed on top of the incubator. The droplet completely dried after 150 minutes, with an evaporation speed of ≈ 0.2 μL/min. We also noticed a change in the electrode surface: the electrodes became darker on the sides, probably due to the coating base (made of saran wrap) deteriorating due to heat exposure in the incubator. The deterioration of the coating base led to the droplets leaking though and being in direct contact with the electrode, which probably caused the corrosion of the electrodes. Also, the obtained images were of too poor quality and did not allow to properly measure the impact of the electrical field on the cells. One possible solution is to have a white background underneath the droplet to enhance the visibility of the cells growth. We are thinking of testing on shinny mirror-like electrodes or with a non-transparent coating base.

For the second experiment, we investigated the impact of the electrical field on the biochemical reaction of the β-galactosidase protein with Xgal. β-galactosidase is a protein produced during the digestion, with the function of breaking down lactose (the main component of diary products) into galactose and glucose. X-gal is a sugar compound used in molecular biology to detect the presence of β-galactosidase. When the two (β-galactosidase and X-gal) are put together, an biochemical reaction (named enzyme-catalyzed hydrolysis) occurs and as a result the mix turns blue. On our fluxel device we dispensed two droplets of 15 μL each, one of the droplet containing β-galactosidase and the second droplet containing X-gal. We then programmed the fluxel to merge the droplets and then mix them by moving them in a circular pattern. We expected to see a blue droplet after the reaction time has passed. We observed that the mixing movement slowed down after a few cycles, until it stopped completely. We believe the behaviour is due to the protein in the droplet, which sticks to the coating surface, thus preventing the droplet from moving. We have to find a coating material that is compatible with proteins. We did not observe any negative impact of the electrical field and the droplet turned blue as expected.

Experiments replicated at Waag's Open Wetlab

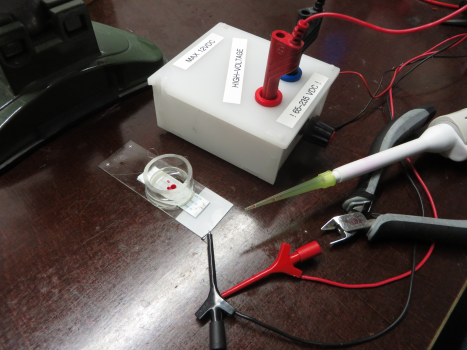

Using Urs' original design we started replicating the experiments in Waag Society's Open Wetlab. The PCB has been made with a Roland Modela MDX-20 milling machine, instead of chemical etching. As a di electric we used peanut oil. The final setup consisted of a hacked IORodeo Gel Electrophoresis Power Supply (driving it up to 300V), the milled PCB, first a layer of peanut oil, than the saran wrap and then another layer of peanut oil. Hereby we demonstrate that this method indeed works

References

Fast Fabricating Electrowetting

Low Cost PCB Digital Microfluidic

First electrowetting microfluidics, the fluid transistor, Cytonix

Videos

On chip Sample preparation utilising EWOD Concept

DNA Lab on a Chip

Sandia Digital Microfluidic Hub

The Electrowetting Display

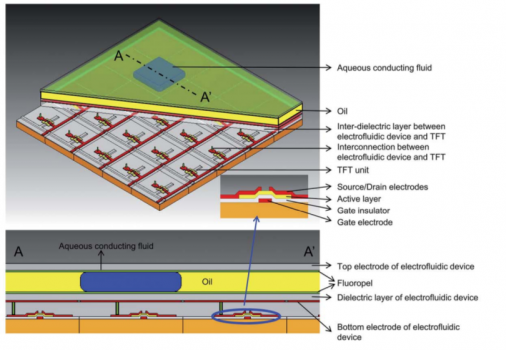

AM-(TFT-)EWOD

Article on AM-(TFT-)EWOD

Patents

1 Toward active-matrix lab-on-a-chip: programmable electrofluidic control enabled by arrayed oxide thin film transistors†

Joo Hyon Noh, a Jiyong Noh, a Eric Kreit, b Jason Heikenfeld b and Philip D. Rack

2 Electrowetting: from basics to applications, Frieder Mugele 1,3 and Jean-Christophe Baret

3 Programmable large area digital microfluidic array with integrated droplet sensing for bioassays, B. Hadwen, a G. R. Broder, b D. Morganti, b A. Jacobs, a C. Brown, a J. R. Hector, a Y. Kubota c and H. Morgan* b